Virtual fruit

Computer-aided modelling is enabling a deeper understanding of fruit microstructure and physiology. By Anna Mouton.

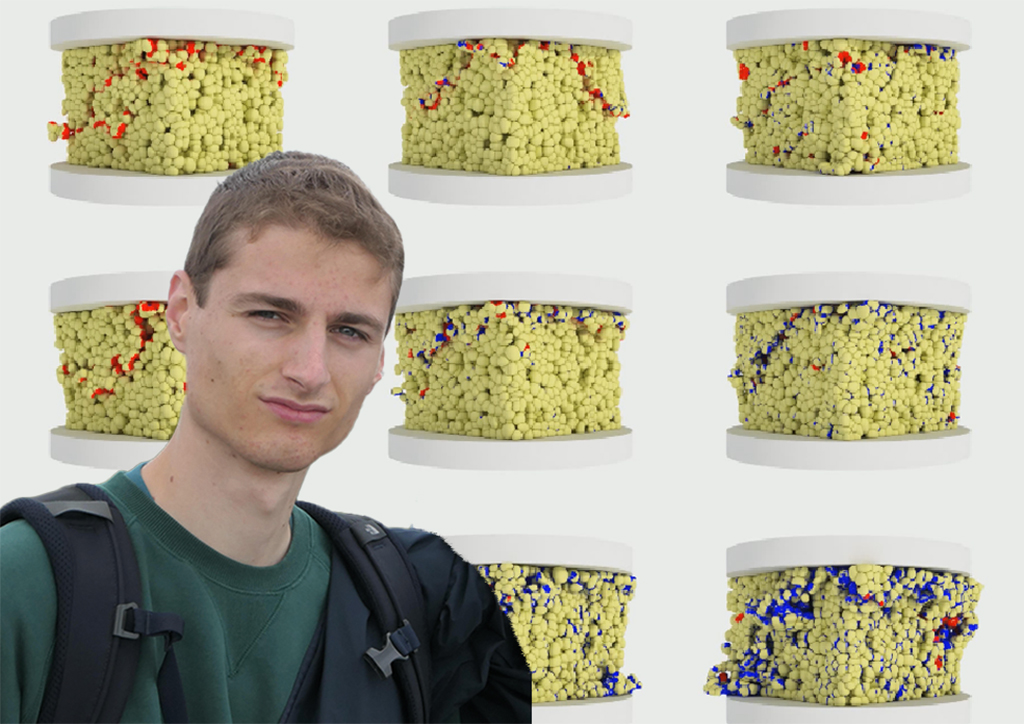

“Why do we want computer models of fruit?” asked Bart Dequeker in a presentation at the recent Hortgro Science Postharvest Symposium. Dequeker is a PhD candidate in bioscience engineering at KU Leuven in Belgium who uses computer-aided modelling to investigate fruit microstructure and gas transport.

His research focuses on the relationship between tissue structure and physiology as fruit develop and mature. His findings will provide new insights into the connection between preharvest factors and postharvest quality.

Dequeker argues that models allow us to simulate processes that we can’t directly observe. “We can study them systematically and make predictions that might seem difficult or practically impossible under experimental conditions,” he said.

Linking pre- and postharvest

Low oxygen levels suppress respiration and delay ripening in apples and pears, so keeping them at low oxygen levels is critical for long-term storage. At the same time, insufficient oxygen levels inside fruit can lead to storage disorders such as browning, cavities, and off-flavours.

Dequeker explained that fruit respond to insufficient oxygen by switching from aerobic respiration to anaerobic fermentation.

“This is disadvantageous for fruit because they can’t produce as much energy from fermentation pathways,” he said. “As a result, you get an energy crisis inside your fruit. They can’t maintain their cellular structure anymore, and their membranes start to decay.”

The challenge is knowing how far oxygen can be safely reduced, as the orchard environment, horticultural practices, cultivar differences, and harvest maturity influence the fruit’s tolerance.

“We need to figure out how preharvest factors impact internal oxygen and damage,” said Dequeker. He aims to determine the physiological basis for storage potential through characterising the fruit’s internal structure.

“Fruit are not uniform,” he pointed out. “They contain different cells and air spaces, which is how they exchange all the gases involved in respiration.”

Each cell is a unit with mechanical properties such as wall stiffness and turgor pressure, and cells are held together like bricks in a wall. Cell size and shape influence cell strength, and the arrangement of cells and spaces governs the porosity of the fruit. Porosity affects gas exchange and tissue texture.

“If we want to optimise our storage procedures or understand which cultivar might store better than another, we must disentangle these factors so we can study them individually and systematically,” said Dequeker. “For that, our research group leans on computer models.”

Mechanics of cells and spaces

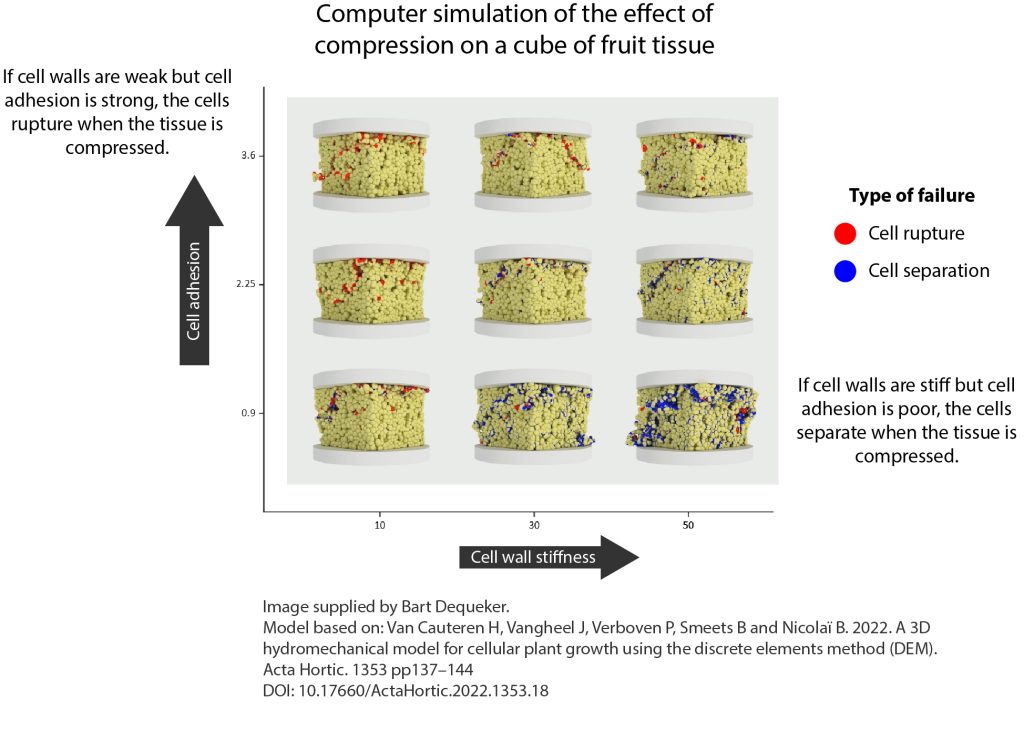

When apple tissue is placed under pressure, cells can either rupture or separate. For a consumer, the former likely represents a better eating experience, as the ruptured cells will release juices and flavours. In contrast, cell separation allows cells to slide past one another, which a consumer perceives as mealiness.

“Our model allows us to study this,” said Dequeker. “It would be very difficult to do experimentally.”

The model simulates a cube of apple flesh containing individual cells. “Each cell can adhere to or slide past other cells, or break or deform,” he elaborates. “We have a good grasp of the physics, and we use software to model all this.”

For example, data on fruit microstructure is based on three-dimensional images generated with X-ray computed tomography. Technological advances enable real-time imaging of fruit undergoing firmness testing. The images provide physical parameters that feed into the model.

Model simulations can also be tested by comparing them to the real-time images.

Dequeker shared the results of simulations that correctly predict the effect of cell-wall stiffness and adherence on texture (Figure 1). As fruit mature, cell walls soften, and adherence weakens. Therefore, cells are less likely to rupture and more likely to slide past one another, resulting in soft, mealy apples.

He also showed how the model predicts the effects of porosity and cell size. As porosity increases from 20% to 30%, tissue firmness drops. Larger cells similarly cause softer fruit. Understanding how the mechanical properties of fruit translate into quality attributes such as texture can, for example, help explain and potentially predict cultivar differences.

“You can’t readily manipulate these things in fruit for experiments,” said Dequeker. “But the model allows us to do this.”

Modelling gas movement

“Measuring gas exchange in fruit is quite cumbersome,” said Dequeker. “Modelling can again be a powerful tool to disentangle these processes that we can’t study easily.”

A fruit uses oxygen and produces carbon dioxide in respiration. These gases move passively through the pores from areas of higher to areas of lower concentration. Therefore, oxygen diffuses from the outside to the inside of the fruit, and carbon dioxide travels in the opposite direction.

Dequeker illustrated gas-exchange modelling with a tomato example. The air paths through the tissue depend on fruit microstructure, which is characterised using X-ray computed tomography. The rate of oxygen consumption and carbon dioxide production is determined experimentally.

“We combine all this in a computational framework, and in the end, we can get to internal gas distributions,” he said. “This is useful because it allows us to answer fundamental research questions about gas exchange.”

In his work on pome fruit, Dequeker examined pore formation in developing apples and pears. He discovered that internal oxygen shortages in young fruitlets drive the formation of air spaces that are crucial for gas exchange in mature fruit.

“We were also able to see how preharvest size variation impacts respiration, and may then later affect storage techniques like respiratory quotient dynamic controlled-atmosphere storage,” he said.

For example, big fruit have a higher ratio of carbon dioxide to oxygen, or respiratory quotient, at their core, putting them at greater risk of fermentation and internal browning in low-oxygen storage. Based on the respiratory quotient, Dequeker’s model could predict where internal browning would occur inside fruit.

“Computer models are obviously very nice for fundamental research,” he concluded. “But they also allow us to optimise our breeding strategies. Also, in future, we could use these models to predict storage performance of new cultivars based on, for example, cell size or porosity.”

View Dequeker’s presentation, including animations of fruit models, on the Hortgro YouTube Channel.